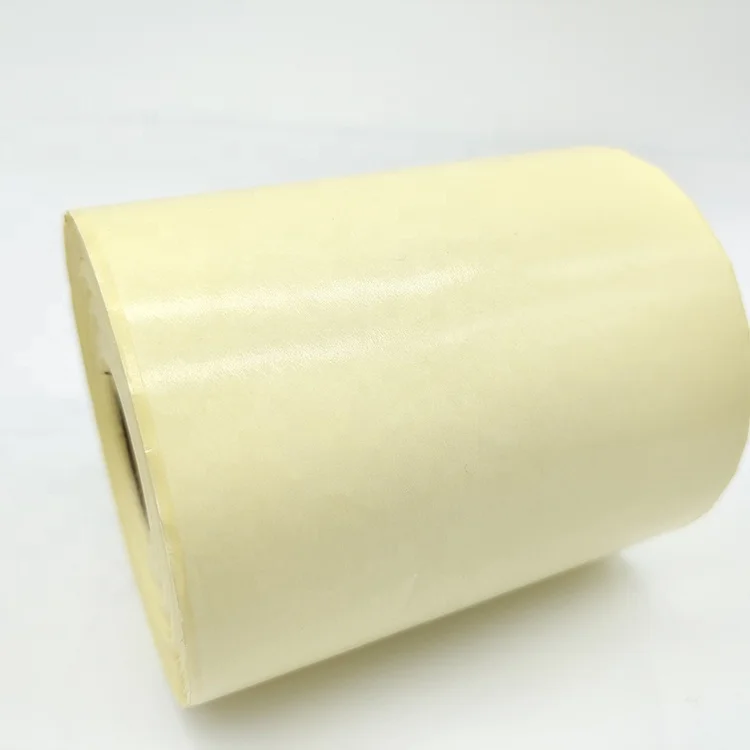

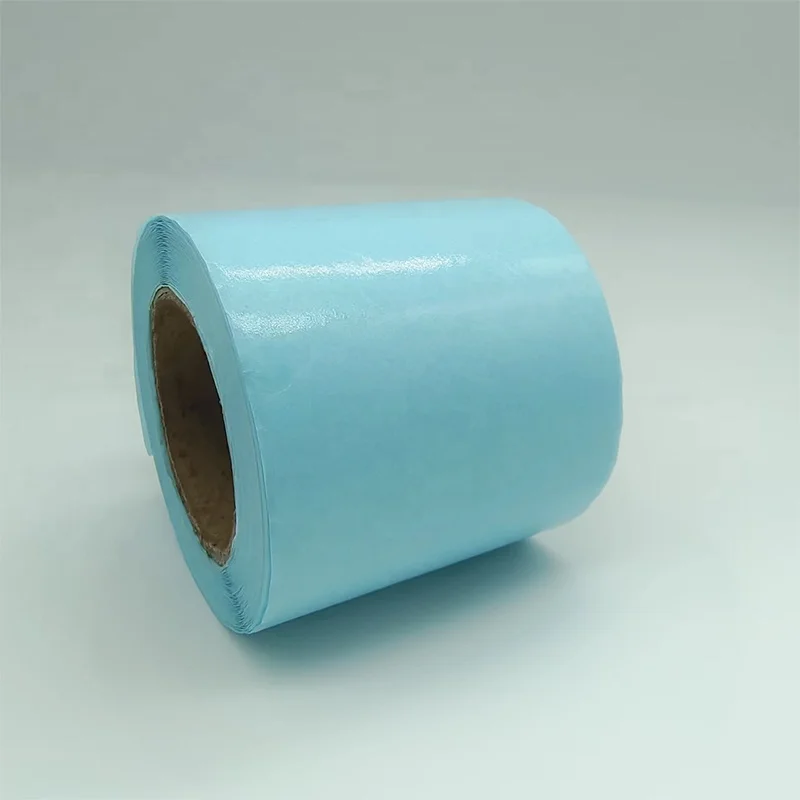

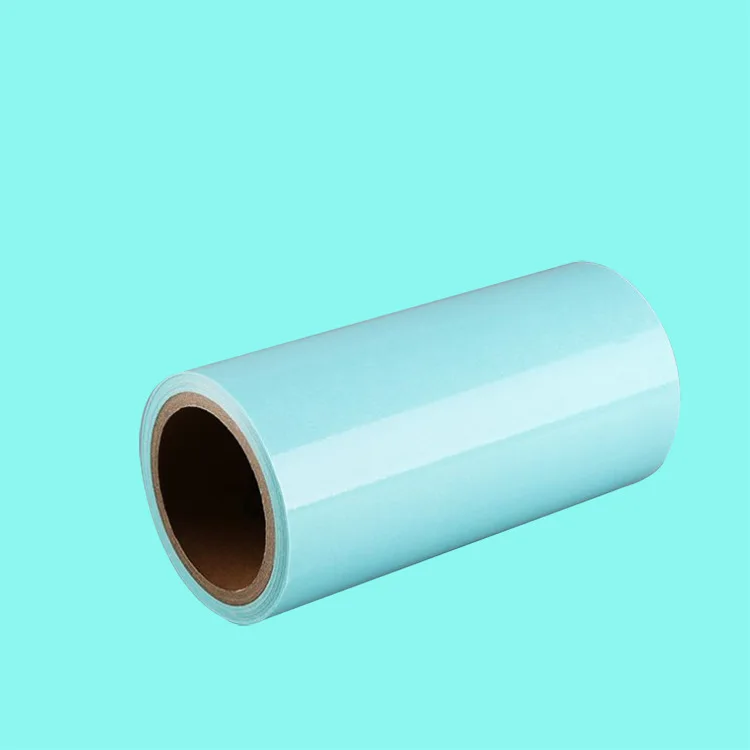

Silicon Release Paper Blue/Yellow/White Glassine Release Paper For Stickers

Item: Silicone Coating Release Paper

Material: Paper

Usage: Thermal Label

Size: Customized

Feature: Waterproof, Oil Proof, Scratch proof

MOQ: 100

- Overview

- Description

- Recommended Products

Product Description

Item |

Silicone Coating Release Paper |

Material |

Paper |

Usage |

Thermal Label |

Size |

Customized |

Feature |

Waterproof, Oil Proof, Scratch proof |

Liner |

White/Blue/Yellow glassine |

Ahesive |

Hot melt Glue |

Sample |

Free sample, Frienght Collect |

Product advantages |

Print smoothly/Clear print/Support customization |

|

Company Advantages

|

10+ years of experience 10000+M2 Factory Floor Area 1vs1 Troubleshooting |

Product usage |

Supermarket / Logistics / Electronic Rquipment / Chemical Industry / Medicine/Food / Clothing |

Related Products

Advantages

Factory & Team

Certifications

Production Process

FAQ

Q1:Are you a factory or trading company?

A1:We are a factory, so we have price advantage than trading company.

Q2:Can you do design for me?

A2:According to your requirement, we can add your company logo,website,phone number or your ideas on paper box or paper roll. Our professional designer can make design to you.

Q3:Can I have a sample order for paper roll?

A3:Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q4:What about the lead time?

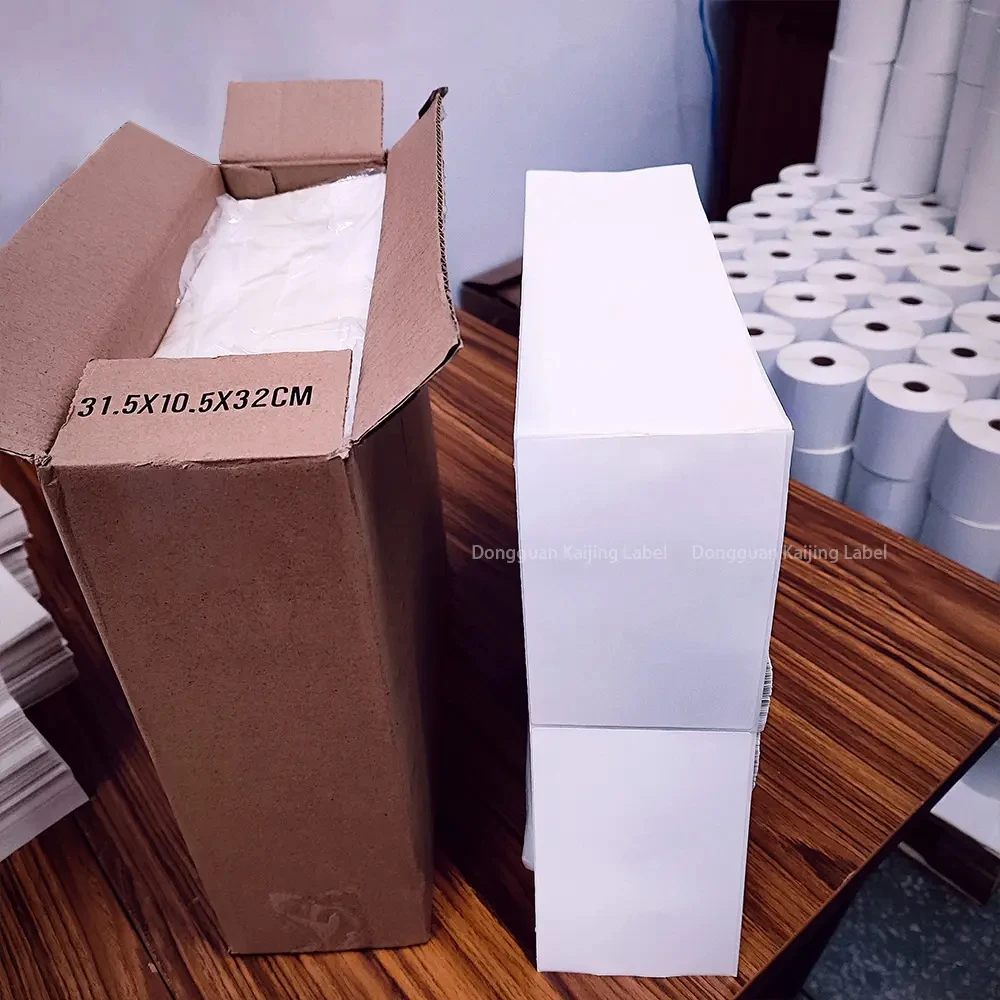

A4:Sample needs 2-3 days, mass production time needs 2-3 weeks for order quantity more than.

Q5:How do you ship the goods and how long doesit take to arrive?

A5:We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional.

The Silicon Release Paper Blue/Yellow/White Glassine Release Paper For Stickers is a high-performance, sticker-focused base material engineered to meet the demands of adhesive sticker manufacturing, packaging, and printing industries. Manufactured in our 7000-square-meter factory with four production divisions and advanced equipment, this Silicon Release Paper stands out for its premium glassine base, precise silicon coating, vibrant color options (blue, yellow, white), reliable release performance, and seamless compatibility with sticker production processes—ideal for sticker manufacturers, printing shops, packaging companies, and small businesses creating custom stickers. Crafted using state-of-the-art silicon coating machines, glassine paper processing equipment, color dyeing systems, and precision cutting tools, the paper delivers consistent release force, tear-resistant durability, color fastness, and smooth surface quality—making it a trusted choice for high-volume sticker production and custom printing. As a modern enterprise integrating production, wholesale, retail, and rigorous quality control, we ensure every roll of Glassine Release Paper meets industry standards for silicon coating uniformity and release reliability. Whether for self-adhesive sticker backing, label manufacturing, or custom print applications, this colored silicon glassine release paper combines functionality, consistency, and versatility to streamline sticker production workflows.

Key Advantages of the Customized Colourful Thermal Label RollsKey Advantages of the Silicon Release Paper (Blue/Yellow/White Glassine)

Factory-Direct Value & 4x6 Inch Shipping Standard Size: As a professional factory with a 7000-square-meter facility and four production divisions, we offer unbeatable competitive pricing by cutting out middlemen—an advantage trading companies can’t match. Our advanced equipment, including synthetic material cutters and size calibration tools, ensures each label adheres to the exact 4x6 inch dimension—the global standard for shipping carriers like USPS, FedEx, UPS, and DHL. This standard size eliminates the need for printer adjustments or carrier compliance checks, streamlining shipping workflows. The factory-direct model supports both small sample orders and large bulk purchases, with consistent quality backed by rigorous process control. Unlike generic labels, our synthetic colorful materials and thermal coating are engineered for shipping environments, ensuring labels withstand handling, stacking, and transit without damage—making them ideal for businesses prioritizing reliability and cost-efficiency.

Vibrant Synthetic Colourful Materials & Crisp Thermal Printing: A standout feature of these labels is their premium synthetic colorful materials that blend vivid aesthetics with durability. Available in a full spectrum of hues (red, blue, green, yellow, and custom shades), the synthetic base resists fading, tearing, and moisture—outperforming traditional paper labels. The colorful design enhances brand visibility on packages, turning plain shipping labels into subtle branding tools. The labels are optimized for thermal printing, producing crisp, smudge-resistant text, barcodes, and graphics without ink or toner—reducing operational costs. The synthetic material’s smooth surface improves print adhesion, ensuring tracking numbers and barcodes remain scannable throughout the shipping process. Whether used for branded packaging or color-coded inventory, the fade-resistant colors maintain their vibrancy from warehouse to customer doorstep.

Convenient Roll Format & Synthetic Durability: These labels are supplied in user-friendly rolls that boost efficiency for high-volume operations. The roll format fits seamlessly into all standard thermal printers and label dispensers, minimizing downtime from frequent reloads during peak shipping periods. Each roll is wound tightly and evenly to prevent creasing or jamming, ensuring smooth, continuous printing. The synthetic material delivers superior durability compared to paper labels—resisting water, oil, dirt, and minor abrasions common in shipping and warehouse environments. Unlike paper labels that tear or smudge, these synthetic labels stay intact in rain, humid storage, or oily factory settings. The material is also flexible, conforming to curved or textured packaging surfaces (e.g., bubble mailers, corrugated boxes) without peeling—ensuring labels stay in place during transit.

Extensive Customization & Streamlined Support: We specialize in customization to align the labels with your brand and operational needs. Backed by our factory’s flexible production capabilities, we offer custom colors (matching brand Pantones), printed elements (logos, slogans, return policies), roll lengths (from 100-label rolls for small businesses to 1000-label rolls for large distributors), and even custom sizes beyond 4x6 inches. Our professional design team collaborates with you to optimize layouts—ensuring branding elements complement shipping info without compromising scannability. Mixed samples are welcome, allowing you to test color accuracy, print quality with your thermal printer, and durability on your specific packaging. For delivery, samples are ready in 2-3 days, mass production takes 2-3 weeks for custom orders, and we ship via DHL, UPS, FedEx, or TNT (3-5 days delivery) with airline/sea shipping options for bulk consignments.

Factory-Direct Value & Premium Glassine Base with Precision Silicon Coating: As a professional factory with a 7000-square-meter facility and four production divisions, we offer unbeatable competitive pricing by eliminating middlemen—an advantage trading companies can’t match. Our advanced silicon coating machines ensure a uniform, thin silicon layer across every sheet of premium glassine paper, delivering consistent release force that prevents adhesive sticker damage during peeling. The glassine base is inherently strong and tear-resistant, outperforming standard paper in withstanding the rigors of sticker manufacturing (e.g., die-cutting, printing, rolling). Our rigorous quality control checks verify silicon coating thickness, release consistency, and paper strength for every batch—ensuring reliable performance for both small sample orders and large bulk production. The factory-direct model supports flexible order sizes, from small rolls for craft sticker makers to large industrial rolls for commercial manufacturers, all at cost-effective rates.

Vibrant Color Options (Blue/Yellow/White) & Color Fastness: A standout feature of this release paper is its three versatile color options—blue, yellow, and white—that cater to diverse sticker production needs. The white glassine release paper is ideal for clear or light-colored stickers, ensuring no color bleed-through and maintaining sticker design integrity. Blue and yellow options enable color-coding during production, helping manufacturers separate sticker types, sizes, or orders efficiently. The colors are applied via advanced dyeing processes that ensure long-lasting color fastness—resisting fading from light exposure, humidity, and manufacturing chemicals. Unlike low-quality colored papers, our glassine release paper maintains consistent hue across entire rolls, preventing mismatched batches and ensuring uniform production quality. The colored base also adds a professional touch to sticker backing, enhancing brand presentation for premium sticker products.

Reliable Release Performance & Compatibility with Sticker Processes: This silicon release paper is engineered for consistent, smooth release that protects adhesive stickers during production and application. The precision silicon coating ensures stickers peel off cleanly without residue, adhesive damage, or paper tearing—critical for delicate stickers (e.g., decorative decals, custom labels). It is fully compatible with all standard sticker manufacturing processes, including digital printing, screen printing, die-cutting, and embossing. The smooth glassine surface ensures crisp print quality for any pre-printed elements (e.g., brand logos, care instructions) on the release paper backing. The paper also withstands heat and pressure from printing and cutting equipment, maintaining its shape and release properties without warping. Whether used for self-adhesive labels, craft stickers, or industrial decals, this release paper ensures seamless production workflows.

Customization Flexibility & Streamlined Support Services: We offer extensive customization to align the release paper with your specific sticker production needs. Backed by our factory’s flexible equipment, we can tailor paper thickness (from lightweight to heavy-duty glassine), roll size (width and length), silicon coating weight (for different adhesive strengths), and even custom colors beyond blue, yellow, and white. Our professional design team can assist with pre-printing elements on the release paper, such as your company logo, website, or sticker application instructions—adding value to your end product. Mixed samples are welcome, allowing you to test release performance with your specific adhesive, compatibility with your printing/cutting equipment, and color suitability for your stickers. For delivery, samples are ready in 2-3 days, mass production takes 2-3 weeks for custom orders, and we ship via DHL, UPS, FedEx, or TNT (3-5 days delivery) with airline/sea shipping options for bulk rolls.

Applications of the Customized Colourful Thermal Label RollsApplications of the Silicon Release Paper (Blue/Yellow/White Glassine)

E-commerce businesses and logistics providers rely on these Customized Colourful Thermal Label Rolls for efficient, branded shipping. Online sellers (Shopify, Amazon, Etsy) use the 4x6 inch rolls as shipping labels, leveraging the standard size for carrier compliance and the colorful synthetic material to add subtle brand flair. The thermal printing compatibility enables on-demand printing of customer addresses and tracking numbers, while the synthetic durability ensures labels survive transit. Large logistics companies use the rolls for color-coding shipments—e.g., red for overnight delivery, green for international orders—speeding up sorting and routing. Third-party fulfillment centers appreciate the roll format’s compatibility with automated printing systems, reducing labor costs. Small home-based businesses benefit from the factory-direct pricing and small sample orders, allowing them to test branded labels without overcommitting. The labels’ scannable barcodes and durable design also reduce delivery errors, improving customer satisfaction.Sticker manufacturers and printing shops rely on this Silicon Release Paper as a core production material for diverse sticker types. Commercial sticker manufacturers use the white glassine release paper for high-volume production of clear stickers, product labels, and promotional decals—leveraging the uniform silicon coating to ensure consistent peeling and adhesive integrity. Craft sticker makers and small businesses prefer the colored options (blue, yellow) for custom die-cut stickers, using color-coding to organize different designs or customer orders. Screen printers value the paper’s smooth surface and heat resistance, which enable crisp, detailed prints on the sticker face while maintaining reliable release. Digital printing shops use the paper for on-demand custom stickers, as it works seamlessly with inkjet and laser printers without smudging or warping. The factory-direct pricing makes it cost-effective for both small-batch craft stickers and large-scale promotional sticker runs, while the consistent quality reduces production waste from damaged or poorly releasing stickers.

Retailers and branded packaging operations leverage the labels’ customization and durability for product branding and inventory. Boutique retailers use the colorful synthetic labels as packaging stickers—adding logos and "Thank You" messages to gift boxes or bags, with the fade-resistant colors maintaining brand consistency. Cosmetic and skincare brands use the labels for product packaging, as the synthetic material resists oil and moisture while the vibrant colors align with brand aesthetics. Wholesale distributors attach the labels to bulk packages, using custom printed info (batch codes, expiration dates) and color-coding to identify product lines. Grocery stores and food retailers use the labels for perishable items, with the synthetic material resisting condensation in refrigerators and the thermal prints keeping expiration dates legible. Pop-up shops and craft fairs sellers use small roll sizes for on-the-spot labeling, customizing labels with prices and brand logos to enhance product appeal. The factory’s customization options make these labels a versatile tool for building brand recognition.Packaging companies and label manufacturers leverage the paper’s durability and release performance for adhesive packaging solutions. Label manufacturers use the glassine release paper as a backing for self-adhesive product labels, ensuring labels peel cleanly from the backing during application to bottles, boxes, or containers. The white option is ideal for food and beverage labels, as it prevents color transfer and meets industry safety standards. Packaging companies use the colored release paper for custom packaging stickers (e.g., "Fragile" decals, brand seals), with blue or yellow adding visibility to important handling instructions. E-commerce packaging suppliers use the paper for custom shipping stickers, as the tear-resistant glassine base withstands transit while the silicon coating allows easy peeling for application. Wholesale distributors of packaging materials offer the rolls to small businesses, benefiting from our factory-direct pricing to provide competitive rates. The paper’s compatibility with die-cutting also enables the production of shaped labels and packaging seals with clean edges.

Industrial facilities and specialized businesses benefit from the labels’ synthetic durability and color-coding capabilities. Manufacturing plants use the rolls for inventory tagging, with color-coding to identify raw materials, work-in-progress, and finished goods. The synthetic material resists oil and dirt on factory floors, ensuring part numbers and barcodes remain scannable. Automotive suppliers attach the labels to small parts boxes, as the flexible synthetic material conforms to packaging and the adhesive holds in warehouse storage. Event logistics companies use the colorful labels for shipping event materials (decorations, merchandise) to venues, with custom colors matching event themes and the durable design surviving transit. Non-profit organizations use the labels for donation shipments, printing logos and handling instructions that stay legible in harsh conditions. Even schools and community centers use small rolls for labeling supplies, with the synthetic material resisting wear and tear from frequent use. Whether for e-commerce shipping, branded packaging, industrial inventory, or community use, the Customized Colourful Thermal Label Rolls 4x6 Shipping Labels Sticker Paper Synthetic Colourful Packaging Label delivers reliable, brand-enhancing solutions tailored to diverse needs.Industrial and specialized industries benefit from the paper’s strength and customizable properties for niche applications. Automotive and electronics manufacturers use the paper as a backing for adhesive decals (e.g., part labels, warning stickers), with the tear-resistant glassine base surviving assembly line handling. The silicon coating ensures decals peel easily during installation without leaving residue on sensitive surfaces. Cosmetic and skincare brands use the white glassine release paper for product label backing, as it maintains a premium appearance and is compatible with the high-adhesion labels used on glass or plastic containers. Event and promotional companies use the colored release paper for custom event stickers (e.g., concert wristbands, festival badges), with blue or yellow adding brand-specific color while ensuring easy peeling for attendees. Art and design studios use the paper for custom art stickers and decals, leveraging the smooth surface for high-quality prints and the reliable release for clean application to canvases or surfaces. Even medical supply companies use the paper for low-tack adhesive labels, as the silicon coating ensures gentle release without damaging delicate packaging. Whether for industrial decals, premium labels, or custom art stickers, the Silicon Release Paper Blue/Yellow/White Glassine Release Paper For Stickers delivers consistent, high-performance solutions tailored to diverse adhesive application needs.