Single Side Coating Synthetic Paper Silicone Release Cups with PE Coating for Beverage Industrial Use Juice Included

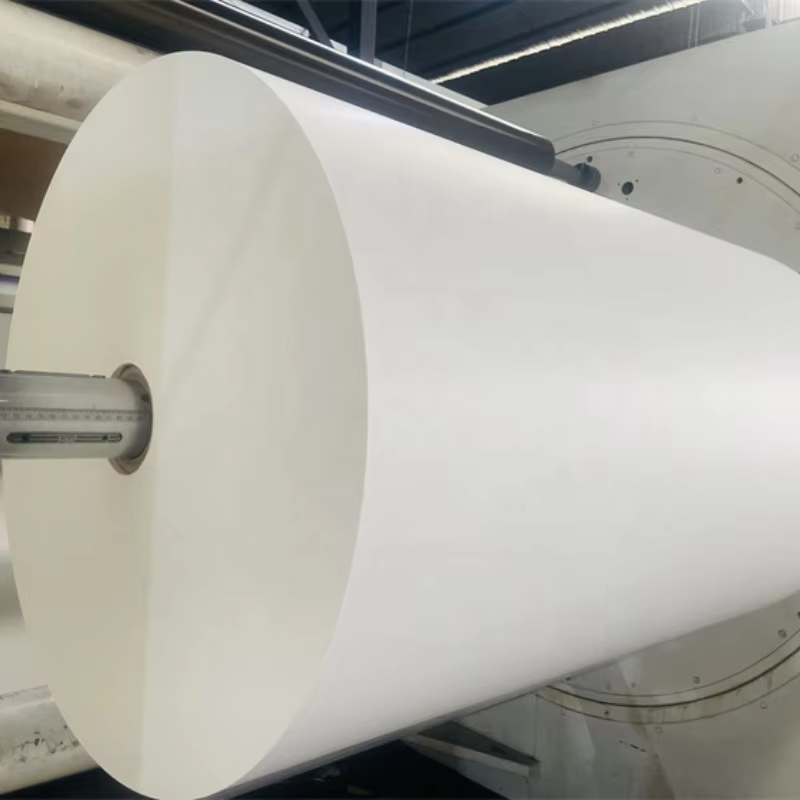

Name: Adhesive paper jumbo rolls

Raw material: paper jumbo rolls

Grammage: 48 gsm, 60 gsm, 80 gsm, 138 gsm, and usual

OEM: Can OEM printing logo & brand

Size: 4"x6"(100X150mm), 100*100mm, anysize customize

MOQ: 100

- Overview

- Description

- Recommended Products

Product Description

Name |

Adhesive paper jumbo rolls |

Raw material |

paper jumbo rolls |

Grammage |

48 gsm, 60 gsm, 80 gsm, 138 gsm, and usual |

OEM |

Can OEM printing logo & brand |

Size |

4"x6"(100X150mm), 100*100mm, anysize customize |

Color |

Plain White (release paper colors can be customized) |

Expiration Date |

3 years |

Core |

40 mm, 1"(25mm), 3"(76mm) |

Length/Diameter |

Accept customized |

Sample |

2-3 days |

Usage |

Express, supermarket, warehouse, shop, shopping mall, etc. |

Our Advantages

Company Profile

Factory & Team

Company Certificate

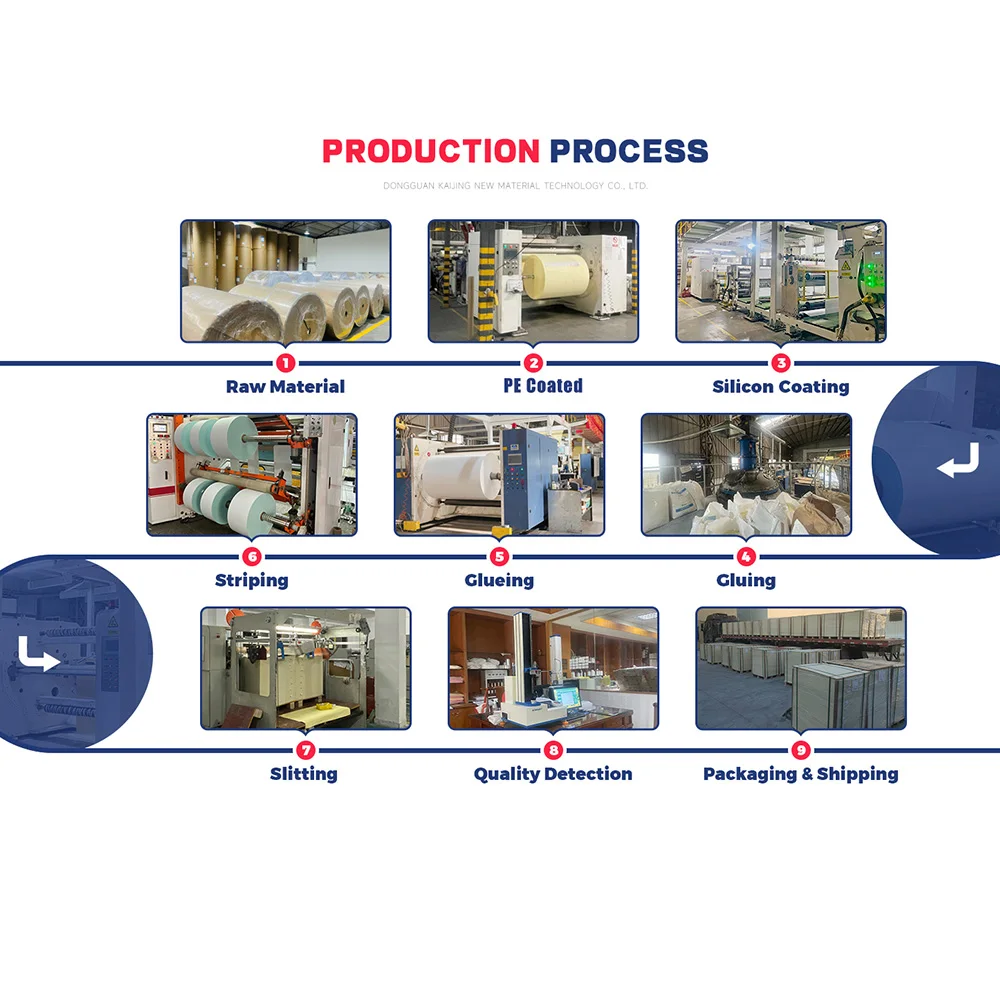

Production Process

FAQ

Q1:Are you a factory or trading company?

A1:We are a factory, so we have price advantage than trading company.

Q2:Can you do design for me?

A2:According to your requirement, we can add your company logo,website,phone number or your ideas on paper box or paper roll. Ourprofessional designer can make design to you.

Q3:Can I have a sample order for paper roll?

A3:Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q4:What about the lead time?

A4:Sample needs 2-3 days, mass production time needs 2-3 weeks for order quantity more than.

Q5:How do you ship the goods and how long doesit take to arrive?

A5:We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional.

The Single Side Coating Synthetic Paper Silicone Release Cups with PE Coating for Beverage Industrial Use Juice Included is a high-performance, beverage-specific packaging solution engineered for the demanding needs of the beverage industry, including juice and other liquid products. Manufactured in our 7000-square-meter factory with four production divisions and advanced equipment, these Silicone Release Cups stand out for their single-side coated synthetic paper construction, food-safe PE coating, reliable silicone release property, and durable design tailored for beverage industrial applications. Crafted using state-of-the-art film machines, silicone coating machines, PE coating equipment, and precision cutting machines, the Silicone Release Cups deliver exceptional liquid resistance, easy release performance, and consistent quality, making them a trusted choice for juice producers, beverage manufacturers, and catering services. As a modern enterprise integrating production, wholesale, and retail, we adhere to rigorous processes and fine management, ensuring every batch of Silicone Release Cups meets food safety standards and industrial quality requirements. Whether for single-serve juice portions, beverage sampling, or industrial beverage packaging, these cups combine functionality and safety to streamline beverage operations and enhance consumer experience.

Key Advantages of the PET Anti-Counterfeit Warranty Void StickersKey Advantages of the Single Side Coating Synthetic Paper Silicone Release Cups

Factory-Direct Quality and Price Advantage: As a professional factory specializing in security labels, we bring unparalleled value to the PET Anti-Counterfeit Warranty Void Sticker. Our 7000-square-meter facility houses the most advanced domestic production equipment, including PET film processing machines, anti-counterfeit printing equipment, and precision slitting machines for paper rolls, ensuring each PET Anti-Counterfeit Warranty Void Sticker has uniform thickness, consistent adhesive strength, and clear anti-counterfeit markings. Compared to trading companies, our factory-direct model eliminates middlemen, offering competitive pricing without compromising security performance. Rigorous quality control—from PET material inspection to anti-counterfeit feature verification—guarantees defect-free PET Anti-Counterfeit Warranty Void Stickers, suitable for small-batch trials and large-scale bulk orders alike.

Durable PET Material with Reliable Tamper Resistance: The PET Anti-Counterfeit Warranty Void Sticker is crafted from high-grade PET material, known for its exceptional durability, water resistance, and tear resistance. Unlike paper-based stickers that are easily damaged, the PET construction withstands harsh environments, including moisture, temperature fluctuations, and minor abrasions, ensuring the sticker remains intact during shipping and storage. Its core security feature lies in the "Warranty Void" activation: when the PET Anti-Counterfeit Warranty Void Sticker is peeled or tampered with, it leaves a clear, irreversible "Warranty Void" message on the product surface, instantly indicating unauthorized access. This tamper-evident design is far more reliable than standard stickers, making the PET Anti-Counterfeit Warranty Void Sticker a robust security barrier.

Anti-Counterfeit Features and Customization Flexibility: A standout advantage of the PET Anti-Counterfeit Warranty Void Sticker is its integrated anti-counterfeit features, which can include holographic elements, microprinting, or custom security patterns tailored to your brand. Our professional design team can further customize the PET Anti-Counterfeit Warranty Void Sticker by adding company logos, serial numbers, websites, or unique brand markings—enhancing brand recognition while boosting anti-counterfeit effectiveness. The product is available as adhesive security label paper rolls, ideal for high-volume application in factories or warehouses. We welcome sample orders, including mixed samples, so you can test the PET Anti-Counterfeit Warranty Void Sticker’s tamper resistance, print quality, and anti-counterfeit features before placing bulk orders.Efficient Production and Global Shipping Support: We prioritize timely delivery to meet your security labeling needs for the PET Anti-Counterfeit Warranty Void Sticker. Sample orders are ready within 2-3 days, allowing you to quickly evaluate security performance and design compatibility. For mass production, lead time is 2-3 weeks for large quantities, ensuring your security sticker rolls arrive on schedule to match production lines. We offer flexible global shipping options: standard delivery via DHL, UPS, FedEx, or TNT arrives in 3-5 days, while airline and sea shipping are available for bulk paper roll orders to reduce costs. Our robust supply chain and trusted logistics partners ensure the PET Anti-Counterfeit Warranty Void Sticker rolls arrive safely and on time, no matter your location—reinforcing our commitment to reliable customer support.Factory-Direct Quality and Price Advantage: As a professional factory specializing in beverage packaging products, we bring unparalleled value to the Single Side Coating Synthetic Paper Silicone Release Cups. Our 7000-square-meter facility houses the most advanced domestic production equipment, including synthetic paper processing machines, precision silicone coating lines, food-grade PE coating machines, and automatic cup-forming equipment, ensuring each Silicone Release Cup has uniform coating thickness, consistent silicone release performance, and sturdy structure. Compared to trading companies, our factory-direct model eliminates middlemen, offering competitive pricing without compromising quality—ideal for beverage manufacturers seeking cost-effective packaging solutions. Rigorous quality control—from synthetic paper raw material inspection to PE coating food safety verification and silicone release performance tests—guarantees defect-free Silicone Release Cups, suitable for small-batch samples and large-scale bulk orders alike.

Food-Safe PE Coating and Liquid Resistance: A core advantage of the Silicone Release Cups is their food-safe PE coating, which is specifically designed to handle juice and various beverages while complying with food industry safety standards. The PE coating creates a reliable barrier against liquid penetration, preventing the synthetic paper cup from becoming soggy or leaking—even when holding acidic juices (like orange or apple juice) or other liquid beverages for extended periods. Unlike uncoated paper cups, the PE coating ensures the cup maintains its shape and structural integrity, avoiding messes during storage, transportation, and consumer use. This liquid resistance also makes the cups suitable for both cold and room-temperature beverages, expanding their versatility in the beverage industry.Single-Side Coating and Silicone Release Performance: The Silicone Release Cups feature a strategic single-side coating design: one side is coated with food-safe PE for liquid protection, while the other side incorporates a high-quality silicone coating that delivers excellent release performance. This silicone release property ensures the cups can be easily stacked without sticking together, streamlining storage and handling in industrial beverage facilities. When used for pre-portioned juice or beverage samples, the silicone release coating also allows for easy separation of individual cups from stacks, reducing downtime and improving operational efficiency. The single-side coating design balances functionality and cost-effectiveness, providing essential performance without unnecessary material waste.

Customization Flexibility and Efficient Support: We offer comprehensive customization for the Silicone Release Cups to align with your beverage brand and industrial needs. Our professional design team can add company logos, brand slogans, product information (like juice flavor or nutritional facts), or custom colors to the cups, enhancing brand recognition on packaging. We also accommodate custom cup sizes to fit different beverage portion requirements—from small sampling cups to standard single-serve sizes. Sample orders, including mixed sizes and custom design samples, are welcome to test liquid resistance, silicone release performance, and print quality. For delivery, sample orders are ready within 2-3 days, mass production takes 2-3 weeks for large quantities, and we ship via DHL, UPS, FedEx, or TNT (3-5 days delivery) with airline and sea shipping options for bulk orders—ensuring timely arrival to match your production schedules.

Durable PET Material with Reliable Tamper Resistance: The PET Anti-Counterfeit Warranty Void Sticker is crafted from high-grade PET material, known for its exceptional durability, water resistance, and tear resistance. Unlike paper-based stickers that are easily damaged, the PET construction withstands harsh environments, including moisture, temperature fluctuations, and minor abrasions, ensuring the sticker remains intact during shipping and storage. Its core security feature lies in the "Warranty Void" activation: when the PET Anti-Counterfeit Warranty Void Sticker is peeled or tampered with, it leaves a clear, irreversible "Warranty Void" message on the product surface, instantly indicating unauthorized access. This tamper-evident design is far more reliable than standard stickers, making the PET Anti-Counterfeit Warranty Void Sticker a robust security barrier.

Anti-Counterfeit Features and Customization Flexibility: A standout advantage of the PET Anti-Counterfeit Warranty Void Sticker is its integrated anti-counterfeit features, which can include holographic elements, microprinting, or custom security patterns tailored to your brand. Our professional design team can further customize the PET Anti-Counterfeit Warranty Void Sticker by adding company logos, serial numbers, websites, or unique brand markings—enhancing brand recognition while boosting anti-counterfeit effectiveness. The product is available as adhesive security label paper rolls, ideal for high-volume application in factories or warehouses. We welcome sample orders, including mixed samples, so you can test the PET Anti-Counterfeit Warranty Void Sticker’s tamper resistance, print quality, and anti-counterfeit features before placing bulk orders.Efficient Production and Global Shipping Support: We prioritize timely delivery to meet your security labeling needs for the PET Anti-Counterfeit Warranty Void Sticker. Sample orders are ready within 2-3 days, allowing you to quickly evaluate security performance and design compatibility. For mass production, lead time is 2-3 weeks for large quantities, ensuring your security sticker rolls arrive on schedule to match production lines. We offer flexible global shipping options: standard delivery via DHL, UPS, FedEx, or TNT arrives in 3-5 days, while airline and sea shipping are available for bulk paper roll orders to reduce costs. Our robust supply chain and trusted logistics partners ensure the PET Anti-Counterfeit Warranty Void Sticker rolls arrive safely and on time, no matter your location—reinforcing our commitment to reliable customer support.Factory-Direct Quality and Price Advantage: As a professional factory specializing in beverage packaging products, we bring unparalleled value to the Single Side Coating Synthetic Paper Silicone Release Cups. Our 7000-square-meter facility houses the most advanced domestic production equipment, including synthetic paper processing machines, precision silicone coating lines, food-grade PE coating machines, and automatic cup-forming equipment, ensuring each Silicone Release Cup has uniform coating thickness, consistent silicone release performance, and sturdy structure. Compared to trading companies, our factory-direct model eliminates middlemen, offering competitive pricing without compromising quality—ideal for beverage manufacturers seeking cost-effective packaging solutions. Rigorous quality control—from synthetic paper raw material inspection to PE coating food safety verification and silicone release performance tests—guarantees defect-free Silicone Release Cups, suitable for small-batch samples and large-scale bulk orders alike.

Food-Safe PE Coating and Liquid Resistance: A core advantage of the Silicone Release Cups is their food-safe PE coating, which is specifically designed to handle juice and various beverages while complying with food industry safety standards. The PE coating creates a reliable barrier against liquid penetration, preventing the synthetic paper cup from becoming soggy or leaking—even when holding acidic juices (like orange or apple juice) or other liquid beverages for extended periods. Unlike uncoated paper cups, the PE coating ensures the cup maintains its shape and structural integrity, avoiding messes during storage, transportation, and consumer use. This liquid resistance also makes the cups suitable for both cold and room-temperature beverages, expanding their versatility in the beverage industry.Single-Side Coating and Silicone Release Performance: The Silicone Release Cups feature a strategic single-side coating design: one side is coated with food-safe PE for liquid protection, while the other side incorporates a high-quality silicone coating that delivers excellent release performance. This silicone release property ensures the cups can be easily stacked without sticking together, streamlining storage and handling in industrial beverage facilities. When used for pre-portioned juice or beverage samples, the silicone release coating also allows for easy separation of individual cups from stacks, reducing downtime and improving operational efficiency. The single-side coating design balances functionality and cost-effectiveness, providing essential performance without unnecessary material waste.

Customization Flexibility and Efficient Support: We offer comprehensive customization for the Silicone Release Cups to align with your beverage brand and industrial needs. Our professional design team can add company logos, brand slogans, product information (like juice flavor or nutritional facts), or custom colors to the cups, enhancing brand recognition on packaging. We also accommodate custom cup sizes to fit different beverage portion requirements—from small sampling cups to standard single-serve sizes. Sample orders, including mixed sizes and custom design samples, are welcome to test liquid resistance, silicone release performance, and print quality. For delivery, sample orders are ready within 2-3 days, mass production takes 2-3 weeks for large quantities, and we ship via DHL, UPS, FedEx, or TNT (3-5 days delivery) with airline and sea shipping options for bulk orders—ensuring timely arrival to match your production schedules.

Applications of the PET Anti-Counterfeit Warranty Void StickersApplications of the Single Side Coating Synthetic Paper Silicone Release Cups

The PET Anti-Counterfeit Warranty Void Sticker’s robust security features and durable construction make it versatile across numerous industries. In the electronics industry, it is widely used for smartphones, laptops, and small appliances—applied to battery compartments, device casings, or packaging to indicate tampering and protect warranty validity. When consumers or unauthorized parties attempt to open the device, the PET Anti-Counterfeit Warranty Void Sticker activates the "Warranty Void" message, clearly signaling that the product is no longer covered under warranty. This protects brands from fraudulent warranty claims and ensures only authorized service technicians access internal components.The Single Side Coating Synthetic Paper Silicone Release Cups’ food safety, liquid resistance, and silicone release performance make them indispensable in the beverage industry. For juice production, they are widely used as single-serve or sampling cups for both retail and industrial purposes. Juice manufacturers use small-sized Silicone Release Cups for product sampling at trade shows or in grocery stores, where the cups’ liquid resistance ensures acidic juices don’t leak, and the silicone release property allows for easy stacking and distribution. Larger sizes are used for single-serve juice portions in convenience stores, cafes, or catering events, with custom logos and flavor labels enhancing brand visibility.

In the appliance and automotive industries, the PET Anti-Counterfeit Warranty Void Sticker secures critical components like engine parts, air conditioning units, or electronic control panels—preventing tampering that could void warranties or compromise safety. High-value goods such as luxury watches, jewelry, or industrial equipment use the PET Anti-Counterfeit Warranty Void Sticker to verify authenticity, with custom anti-counterfeit features like holograms adding an extra layer of protection against counterfeiting. The adhesive security label paper roll format is ideal for factory production lines, enabling efficient, high-volume application on assembly lines. Additionally, the PET Anti-Counterfeit Warranty Void Sticker is used for medical devices, where tamper resistance is critical to ensure product safety and regulatory compliance. Whether for warranty protection, authenticity verification, or tamper detection, the PET Anti-Counterfeit Warranty Void Sticker delivers reliable security performance that safeguards brands and consumers alike.In beverage industrial facilities, the Silicone Release Cups excel for pre-portioned ingredients or intermediate processing steps. For example, beverage manufacturers use them to hold pre-measured fruit purees or juice concentrates during production, leveraging the PE coating’s liquid resistance and the silicone release’s easy stacking. Catering services and event organizers rely on the cups for serving a variety of non-carbonated beverages—including iced tea, lemonade, and smoothies—where the cups’ durability and leak-proof design ensure hassle-free service. The cups also suit vending machine operators, as their sturdy construction and silicone release property make them compatible with vending machine dispensing systems. Additionally, they are used in food testing laboratories for beverage quality control, holding small liquid samples safely. For craft beverage producers, the customization options allow for unique branding on cups used for local farmers’ markets or artisanal beverage tastings. Whether for juice sampling, single-serve beverage packaging, or industrial processing, the Single Side Coating Synthetic Paper Silicone Release Cups deliver reliable performance that meets the beverage industry’s strict safety and operational demands.